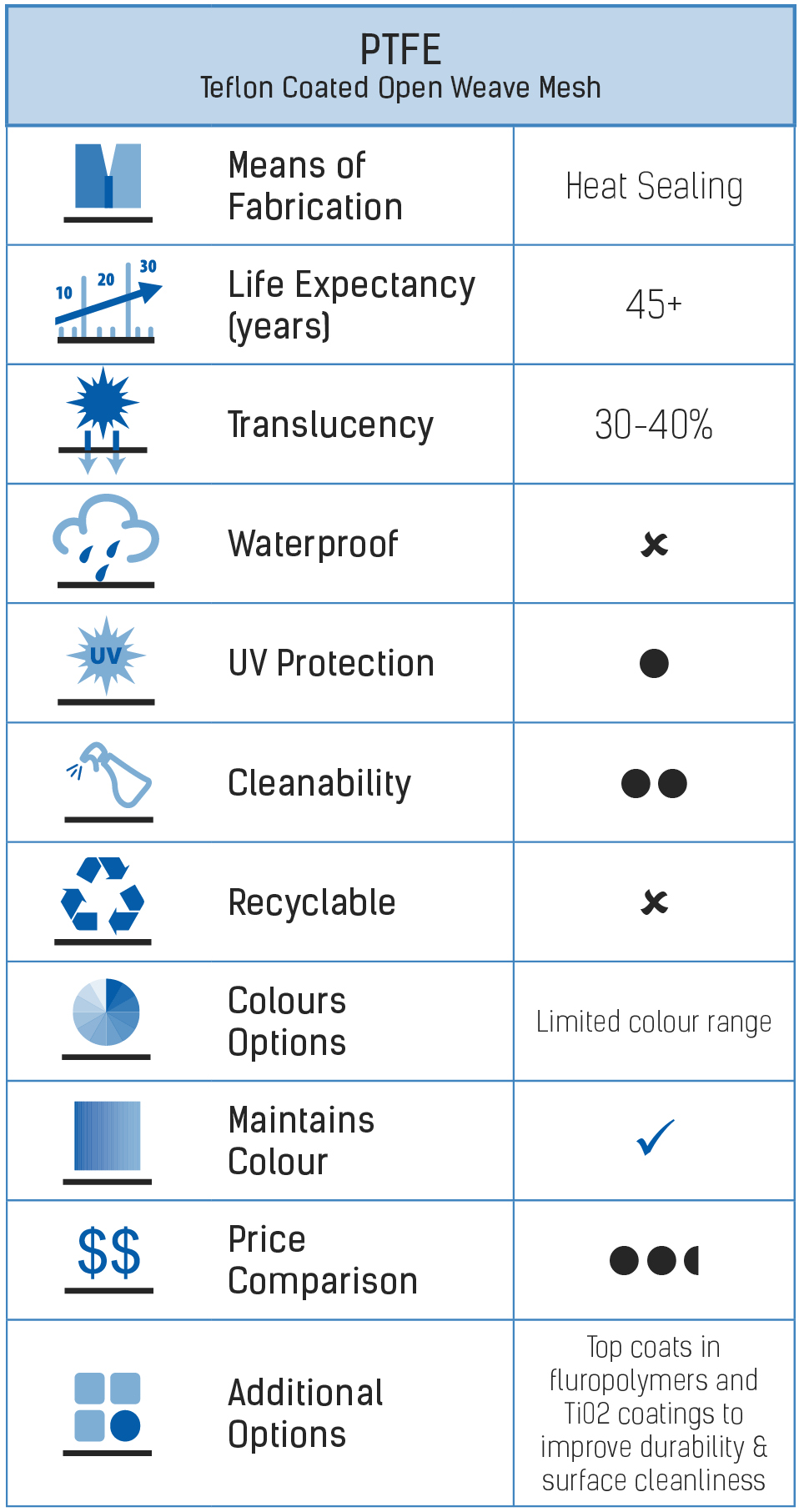

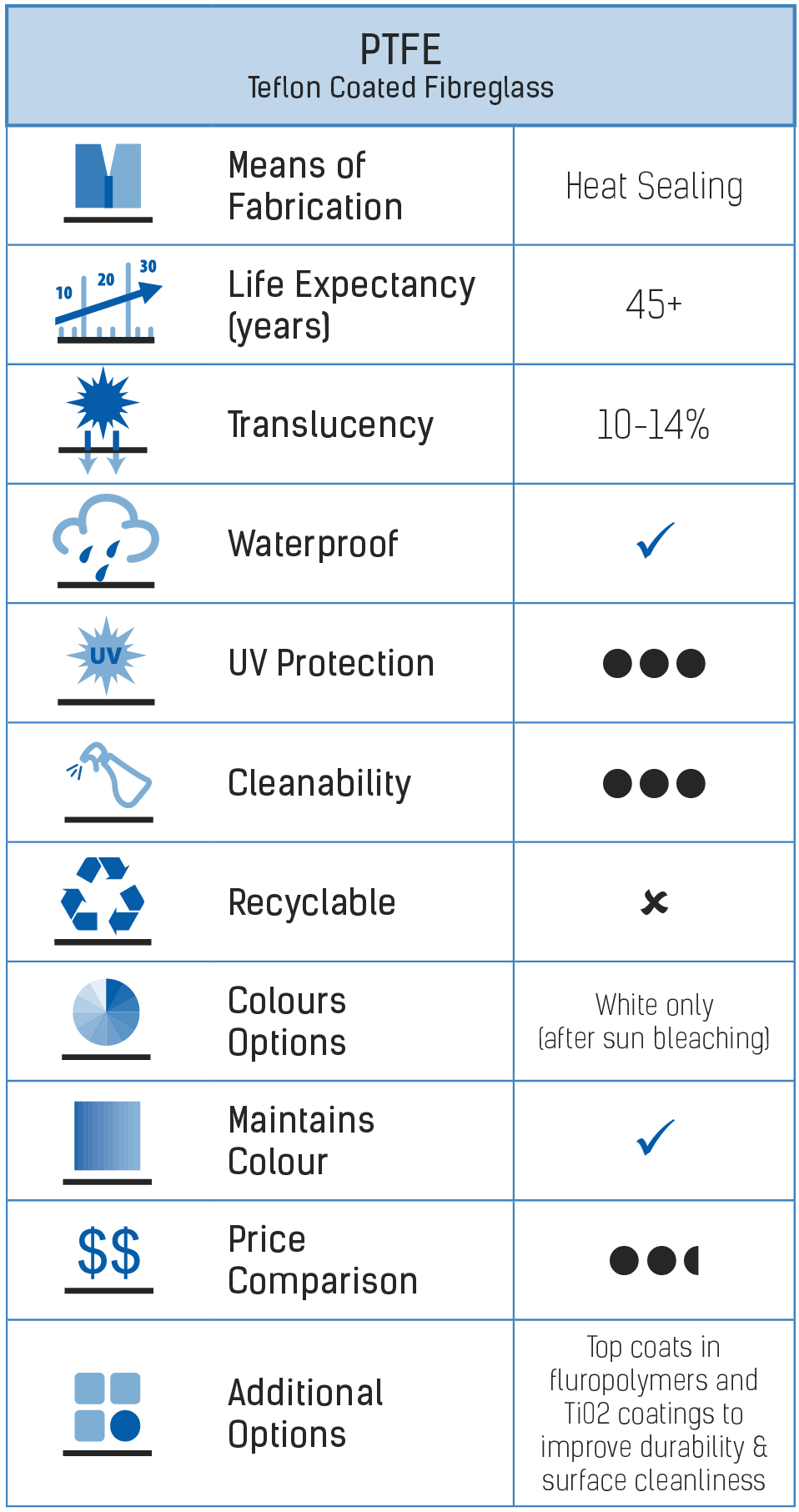

PTFE: An Extremely Durable and Long Lasting Membrane

PTFE (polytetrafluoroethylene) coated fibreglass membranes are composed of a woven glass-fibre base cloth, pre-coated with a silicon layer to prevent moisture absorption, and then coated with liquid PTFE. This process produces a membrane fabric which has low water vapour permeability and excellent UV, anti-adhesive and light translucency properties.

PTFE membrane combines the strength, flexibility, and fire-resistant properties from the fiberglass mesh, with the unrivalled weatherability and chemical resistance from the polytetrafluoroethylene coating. Overall PTFE provides the most aesthetic, durable, low maintenance, and translucent cladding option for membrane structures and tensile architecture solutions and lends itself to many bespoke architectural designs and structural applications.

A confirmed design life of at least 45 years, some of the first PTFE membrane structures built in the 1970’s still standing. MakMax have undertaken mechanical testing of material from a dismantled structure that still exhibited a tensile strength greater than its specified value after 25 years in service.

PTFE Membrane Structures / Tensile Architecture Application

Known for its strength, durability, and its ability to offer a range of translucency to architectural design, MakMax chooses architectural PTFE fabric for a wide range of applications.

As well as regular PTFE membrane; blackout, low translucency and porous mesh options are available to allow architectural design freedom.

- Membrane Roofing: High translucency, strength, aesthetics, and self-cleaning properties of the PTFE membrane make it the perfect membrane for stadium roofs, bowling green canopies, sports court canopies, sporting club grandstands and retail or commercial atrium roofing.

- Shade Structures & Awnings: Strong, long-lasting, stable, and with effective protection against UV, PTFE is ideal for retail walkways and shade areas; hotel and restaurant alfresco dining; COLAs (covered outdoor learning areas) for schools and universities, and public transport waiting areas.

- Facades & Interiors: Prized for its sound absorption characteristics and fire-resistant qualities, PTFE has the ability to create architecturally stunning facades and interior panelling or soffits. PTFE Mesh is especially suitable for facades, fostering extremely effective light transmission and heat control.

What Are The Benefits of PTFE Membranes?

Strength & Durability

- The woven glass fibre yarns give PTFE membrane its superior mechanical strength. It can span significant distances with minimal secondary supporting elements, making it the material of choice for large lightweight structures.

- Being chemically inert, the PTFE coating does not degrade or age under UV exposure, ensuring the fabric maintains its bright white colour throughout its lifespan.

- PTFE fabric can be installed in climates ranging from the frigid arctic to the scorching desert heat, capable of maintaining strength and flexibility in temperatures from -73°C to +232°C.

Flexibility

- The glass fibre filaments, known as beta glass, are the smallest diameter available in tensile membrane fabrication, and provide the membrane with maximum flexibility.

- The fibers are drawn from hot melt glass through platinum dies into continuous filaments, and are then twisted and plied into yarn bundles. The yarns are woven into a wide structural fabric, which is then coated with PTFE to complete the process. Under normal conditions, the fabric behaves elastically and does not undergo significant stress relaxation or creep.

High Translucency

- PTFE membranes transmit up to 14% of natural light, reducing the need for artificial lighting throughout the day and creating a natural colour-correct and glare-free environment.

- This same property allows for creative visual effects with great impact when backlit at night, while strong reflectivity allows for even under-canopy luminance though uplighting.

Comfort

- PTFE reflects much of the sun’s energy, keeping the air temperature under a PTFE membrane roof much cooler than conventional roofing materials.

- When inistalled in inner-city areas, these reflective characteristics help to reduce the Urban Heat Island effect.

- In a recent study, researchers found that on a 35ºC day, the under-surface of a PTFE membrane roof was up to 9ºC cooler than a metal roof. This translates in approx. 20% less radiant heat making the overall air temperature under a membrane roof more comfortable.

- Reduced shade lines and true colour perception due to its high translucency offer a glare-free, natural-light feel for people inside a structure.

Low Maintenance (Self-cleaning)

- The coefficient of friction of PTFE membrane is one of the lowest of any solid in existence, meaning almost nothing will stick to it.

- The low surface energy of membrane coating minimises the capacity of dust, dirt, and pollutants to stick to the surface and are easily washed away during normal periods of rainfall.

- PTFE is a hydrophobic material, so water will bead and run-off along natural contours, aiding the self-cleaning properties.

Fire Performance

- With noncombustible glass fibre at its core, the PTFE coating on architectural fabrics maintains a very high melting point (around 327°C), there are very few situations where PTFE would be damaged by heat.

- In a fire situation, the membrane does not present burning or flaming droplets and will not contribute to flame propagation.

- Excellent fire performance characteristics to AS1530 parts 2 and 3 (Fire-resistance tests for elements of construction), and also meets and exceeds the most stringent fire codes throughout the world.

Case Studies

What is ePTFE?

ePTFE, or expanded PTFE was discovered in 1969 by industrial chemist, Bob Gore while he was working with DuPont. In a series of experiments with the PTFE polymer, Gore was able to expand the PTFE structure by up to 10 times it’s original size. The expanded material was 70% air, enabling Gore to fill the ePTFE with complementary materials. The resulting ePTFE was incredibly lightweight yet strong and could be crafted into multiple forms.

The ability to adapt ePTFE into different forms has enabled far-reaching applications for many industries, from waterproof clothing manufacture to cabling materials found on the Mars Rover.

In architectural applications, ePTFE can be used to create a lighter, more flexible membrane with much higher light transmission. MakMax Australia deployed eTFE infill panels in the Optus Stadium Roof to allow extra natural light transmission.

The most common application of eTFE in architectural fabrics is the use of eTFE thread. The sewn edges around the perimeter of a fabric panel or the sewn pocket holding a rope or cable edge are one of the main points of failure on fabric under tension. We use Gore Tenara ePTFE sewing thread in fabrication of all our membrane structures due to it’s enhanced strength and structural properties.

ePTFE thread is weather-proof, UV resistant, unaffected by extreme heat or cold and is unaffected by acids, alkaline solutions, bleach and cleaning chemicals.

PTFE Bowling Green Canopy. Salisbury Bowling Club, Adelaide SA

PTFE Awnings. Flynn by Crystalbrook Collection Hotel Cairns QLD.

PTFE Facade. RNA Large Animal Pavilion, Brisbane QLD.

PTFE Facade & Dual Translucency Roof. Anna Mears Velodrome, Brisbane QLD.

PTFE Petal Shaped Roof. Blaxland Riverside Park Kisok, Sydney NSW.

Would You Like More Information About PTFE Membrane Structures?

Contact us today to discuss your project requirements. We are the market leader in the design, engineering, fabrication and installation of custom fabric structures for a wide variety of applications and industries. We have extensive project experience and offer endless possibilities when it comes to custom design solutions to meet your needs.